|

Produt Name

|

SS V001 Serra

|

|

Product Type

|

Engineered Stone Quartz Slabs

|

|

Sizes

|

3000x1400mm,3000x1600mm,

3200x1400mm, 3200x1600mm etc.

|

|

Thickness

|

12,15,18,20,30mm,etc.

|

|

Harness

|

7 Mohs

|

|

Temperature Resistance

|

≥300ºC

|

|

Quality control

|

Safe

packing, Color difference control.

All

products are checked by experienced QC piece by piece and then pack.

|

|

MOQ

|

100 Square Meter

|

|

Service

|

Manufacturer can offer high quality, competitive

price and swift delivery.

|

Recently, quartz has gained in popularity

because it offers more aesthetic choices than natural stone. Quartz countertops

have very modern, elegant aesthetics. As engineered stone surfaces, they also

have very few – if any – imperfections.Unlike natural stone, quartz countertops

are manufactured in a controlled setting. The ground quartz crystals are

carefully mixed with just the right amount of resin, pigments, and other

materials to create a strong and stylish countertop.

Engineered Quartz has a durable, non-porous

surface that is both scratch and abrasion-resistant, allowing it to maintain

its original luster. It doesn’t require sealing.When you are cleaning your quartz countertops, all you will need is a

towel, dipped in soap and water. After having done this, you can start wiping

them off. For hardened spills, you can scrape quartz with a soft plastic or

rubber tool, for example a rubber spatula. Never use metal tools, and always be

careful not to drive sharp edges into the stone as the resin can be damaged.

Product Show:

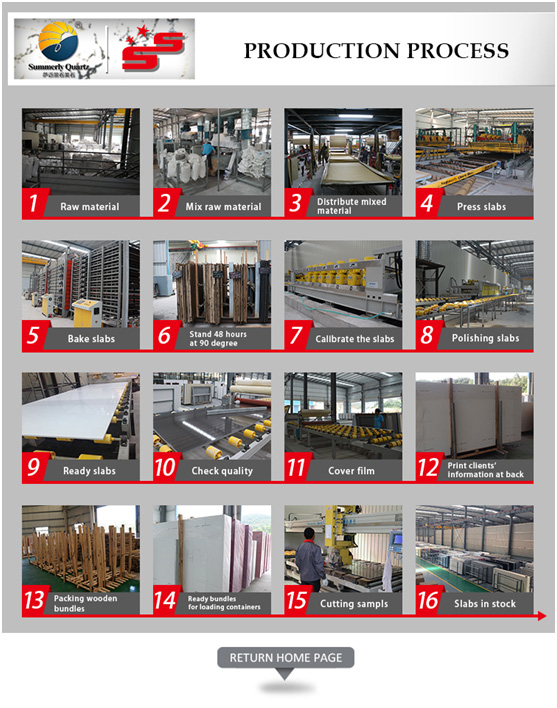

Production Engineering:

1. The process begin with a rigorous

inspection of raw materials.

2. Feeding natural quartz raw material and

polymer resins and inorganic pigments in to mixers and blending them together.

3. After stirring the mixture, then pouring

them into a mold and form them into slab size.

4. Pressing: Then the slab is compacted by a

special vacuum and vibration process at pressure machine.

5. The slab then moved to the curing kiln and

heated for a period time which give them ultimate strength and solidity.

6. Trimming edges, leveling , thicknessing

and polishing surface to perfect finished.

7.Finally, the quartz stone slabs passed through

quality inspection and packed with a plastic film.

Packing wooden

crate (slab) wooden box (tiles/

countertop)