Item No:

|

Calacatta V022

|

Product Type

|

Artificial Quartz Stone

|

Composition:

|

93% quartz powder, 7% resin and pigment.

|

Standard Size:

|

3000x1400mm,3000x1600mm, 3200x1400mm, 3200x1600mm etc.

|

Thickness:

|

20mm,30mm

|

Resistance to Deep Abrasion

|

5×10-2g/cm2

|

Mohs Hardness:

|

6.0-7.0Mohs

|

Bulk Density:

|

>2.30g/cm3

|

Quality Control:

|

Color difference control,Safe packing,

Thickness tolerance: /-1mm

All products are checked by experienced QC piece by piece and then pack.

|

Package:

|

Plastic inside strong seaworthy wooden bundle outside

|

Payment Terms:

|

30% pre-deposit via TT, the balance paid by TT or L/C at sight after cargo prepared

|

When it comes to kitchen countertops, quartz is on the rise, especially those patterns that mimic the natural appearance of real stone. Quartz is known for realistically mimicking a wide variety of countertop styles, but the most popular is marble look quartz. Quartz countertops are becoming more and more popular because they’re pretty easy to maintain and can withstand daily wear better than some of the natural stone options. Quartz is a very durable material with a long life. It’s scratch resistant, stain resistant, and extremely hard to chip or crack. Quartz is one tough material.

Quartz countertops are very durable and low-maintenance with performance qualities similar to granite that saves a lot of time everyday. Quartz doesn’t need sealing and it is very easy to clean. For day to day cleaning, just use mild soap and water. Make some soapy water and using a soft cloth wipe your surfaces. Follow up with wiping your surfaces with a clean, damped cloth. For deep cleaning, Spray generous amount of glass cleaner evenly on your countertops until they’re saturated. Let it sit for a few minutes and wipe it down with a wet soft cloth. This will also leave your countertops looking shiny!

Usage:

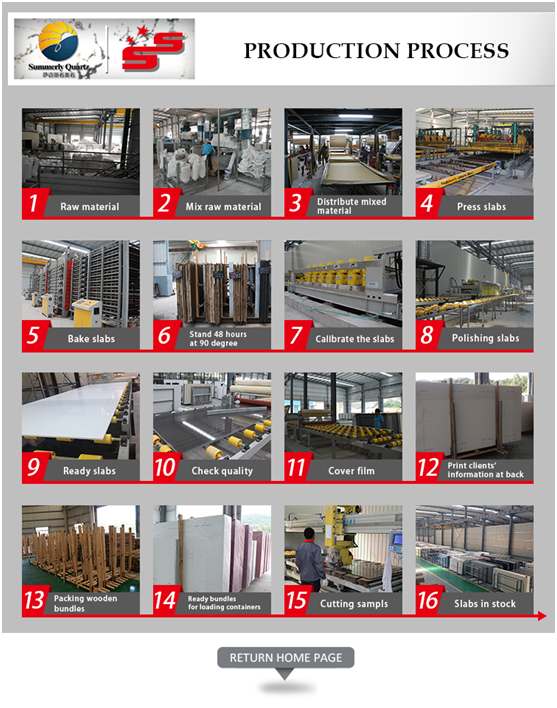

Product Process:

About the Quality:

1. Thickness: Quality allowed +-0.5mm. In production, we will measure the thickness three times to make sure it is qualified.

2. Size: We will make the slab 20mm longer and wider to make up the lack of corner problem that possiblely happen.

3. Production line QC will inspect the slab surface meter by meter to make sure the there are no bubble and other quality problem.

4. General QC will inspect the quality again, to make sure the whole quality is good.

5. We supply two years's quality warranty, if you found any quality problem within two years after you received the slabs, you can contact with our saler.