Type

|

Artificail Stone

|

Model No

|

Calacatta VV-130

|

Specification

|

3000x1400mm,3000x1600mm, 3200x1400mm,etc.

|

Thickness

|

20mm,30mm etc.

|

Tolerance

|

+/-1mm

|

Temperature Resistance

|

≥300ºC

|

Specular Gloss

|

44.5

|

MOQ

|

100 square meter

|

Surface finished

|

Polished,Honed, etc.

|

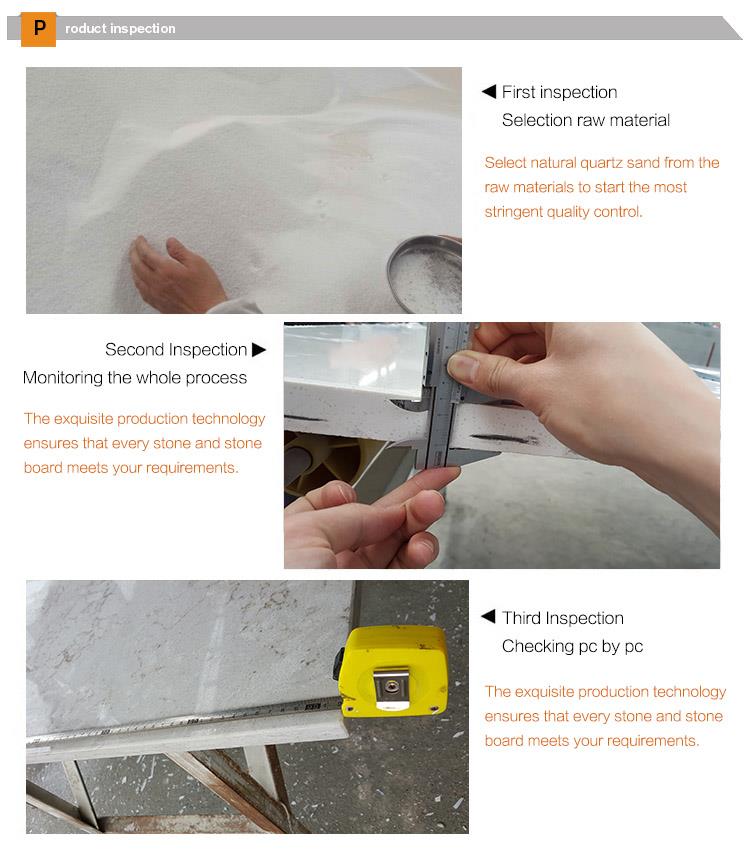

Quality Control

|

Color difference control,Safe packing,

Thickness tolerance: /-1mm

All products are checked by experienced QC piece by piece and then pack

|

Payment Terms

|

T/T,L/C

|

Sample Request

|

Free Sample with Freight Paid by Customer

|

Packing

|

Slabs: 10-20pcs pack in a seaworth bundle (after fumigation)

|

Quartz countertops are engineered. They are 93-95% natural ground quartz combined with polymers, resins and pigments. The resin binds the elements, creating a very strong, non-porous, and scratch resistant material. Because it is non-porous, polarstone requires no sealing, ever. Quartz countertops is a low maintenance surfacing material with the appeal of natural stone, but without the shortcomings like the need to seal annually to prevent staining. Quartz, or engineered stone, is highly resistant to the routine wear and tear of daily life. Because quartz is made from a tough combination of natural crystals and resin, this product is very durable and long lasting.

When it comes to designing a quartz countertop, you aren't limited to traditional, squared edge treatments. There are a number of different edge treatments to choose from, with beveled or rounded styles. Inlays add a touch of elegance to a countertop surface by accenting the contours of the counter. On the other hand, the matte sheen on honed quartz can only be achieved through the removal of the polished surface, which requires fabrication and processing. That is why honed quartz is considered an option for upgrade.

Application:

About the Quality:

1. Thickness: Quality allowed +-0.5mm. In production, we will measure the thickness three times to make sure it is qualified.

2. Size: We will make the slab 20mm longer and wider to make up the lack of corner problem that possiblely happen.

3. Production line QC will inspect the slab surface meter by meter to make sure the there are no bubble and other quality problem.

4. General QC will inspect the quality again, to make sure the whole quality is good.

5. We supply two years's quality warranty, if you found any quality problem within two years after you received the slabs, you can contact with our saler.

Prodcut Inspection: