|

Product name

|

Artificial

Quartz Stone

|

|

Material

|

High

purity acid-washed 93% quartz stone grain, 7% resin and a small proportion of

inorganic pigment.

|

|

Model Number:

|

SS1836 Anthra

Black

|

|

Size

|

Slabs Size: 3000x1200mm,3000x1600mm, 3200x1600mm,etc

Tile Sze: 3300×300,300×600,600×600 and welcome customized.

Countertop Size: 48 x 26". 70 x 26", 78 x

26", 96"x26", 108"x26"

Vanity top Size:22"x25",

22"x31", 22"x37", 22"x49", 22"x61", 22"x73"

Customized

Sizes are Available.

|

|

Thickness

|

12mm 15mm 18mm 20mm 30mm

|

|

Bulk Density

|

>2.30g/cm3

|

|

Mohs′ Hardness

|

5~7

|

|

packing

|

packed

with strong wooden crates and foam, film inside.

|

|

Application:

|

kitchen

worktops, bathroom vanity tops and floor tiles, Wall tile, Decorative

Borders, threshold, windows sill, tub surround, and so on.

|

Quartz countertop choices are abundant and

there are numerous selections in styles colors and patterns. In addition,

Quartz can even be fashioned to look like natural granite or marble. Quartz countertops are made up of natural quartz stone with resin in a ratio of

93% quartz material to 7% resin binder and color additives.

The Artificial Quartz Stone is nonporous,

and thus does not require sealing. The surface of quartz countertops won’t

absorb liquids, making clean up easier and more effective.You are good to go

armed with just soap and water. Avoid scouring pads, which can dull the

surface, and harsh chemicals that could break down the bonds between the quartz

and resins.

Production Engineering:

1. The process begin with a rigorous

inspection of raw materials.

2. Feeding natural quartz raw material and

polymer resins and inorganic pigments in to mixers and blending them together.

3. After stirring the mixture, then pouring

them into a mold and form them into slab size.

4. Pressing: Then the slab is compacted by a

special vacuum and vibration process at pressure machine.

5. The slab then moved to the curing kiln and

heated for a period time which give them ultimate strength and solidity.

6. Trimming edges, leveling , thicknessing

and polishing surface to perfect finished.

7.Finally, the quartz stone slabs passed

through quality inspection and packed with a plastic film.

Packing wooden

crate (slab) wooden box (tiles/

countertop)

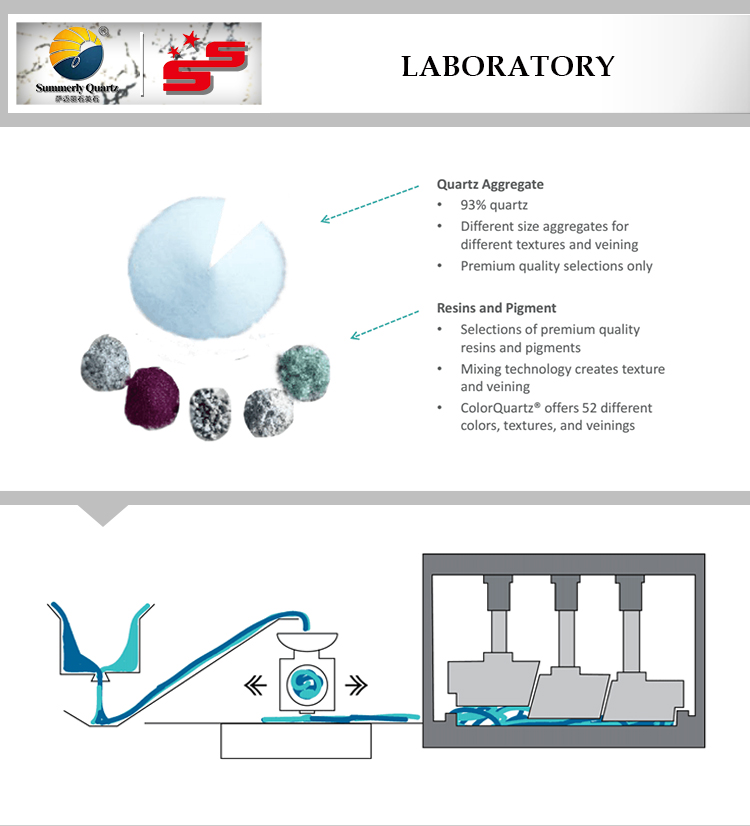

Laboratory: