|

Item No

|

SQ7117

Cloudy

|

|

Composition

|

93%

quartz stone,7% resin,pigment,and other materials.

|

|

Size

|

3000x1400mm,3000x1600mm,3200x1600mm,etc

|

|

Thickness

|

12, 15, 18, 20, 25, 30mm

|

|

Flexural

Strength

|

25~35Mpa

|

|

Quality Control

|

Polished degree:90 degree or up.As customs' requirement

Thickness tolerance: /-1mm

All products checked by experienced QC and then pack

|

|

Package

|

Strong seaworthy wooden crated with fumigation.

Inner packing: with foamed plastic materials packed inside.

Packed directly in wooden crates, with safe support to protect the

surface & edges, and prevent rain and dust.

|

|

Payment

|

Usally T/T (30% deposit / 70% before loading ), 100% L/C at sight.

|

Quartz countertops are 93% natural quartz

material t0 around 7% resin binder which helps make it extremely solid, dense,

and durable. It is more hefty and almost impossible to crack or chip unlike

Granite and Marble.

Quartz countertops come in a broad spectrum

of colors and patterns, from light, dark tones. Quartz is a man-made material

that combines the strength and durability of resin with distinctive of natural

quartz crystals. This material can be tinted in a nearly unlimited range of

shades to match any interior color scheme.

Unlike natural stones, engineered quartz

countertops are non-porous.

With quartz, you don’t have to worry about

any of that. Since it’s a non-porous material, You don’t need to seal it and

you never have to worry about liquid or bacteria penetrating the surface.

Ideal Use:

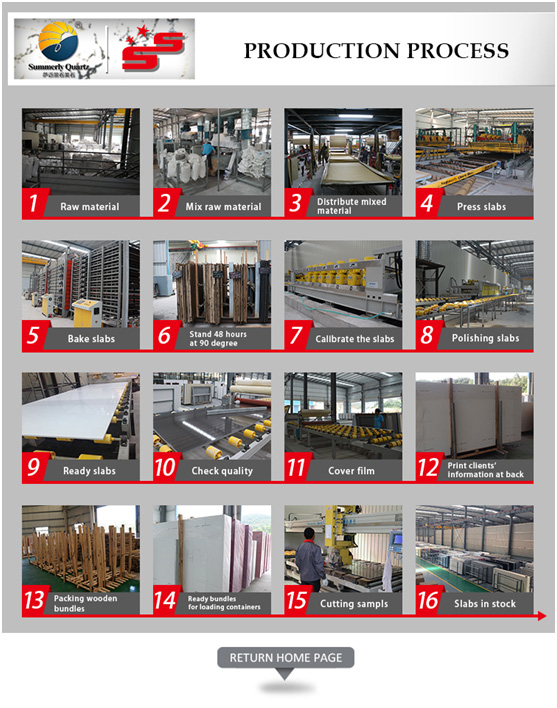

The Production Process:

1.

The process begins with a strict inspection of raw materials.

2.

The natural quartz raw material and polymer resins and inorganic pigments are

put into the mixers and mix together.

3.

After mixing, pour them into a mold and form them into slab size.

4.

Pressing: Then the slab is compacted by a special vacuum and vibration process

at pressure machine.

5.

Then the slab is moved to the curing kiln and heated for a period time to make

their final strenth and srurdiness.

6.

Cut edges, flat , thicknessing and polishing surface to perfect finished.

7.

Finally, through quality inspection and plastic film packaging