Item Name

|

SS6143 Drift Grey

|

Composition

|

High purity acid-washed 93% quartz stone, 7% polymer material and a small amount of inorganic pigment.

|

Size

|

Slab:3000mm x 1400mm,3000mm x 1600mm,3200mm x 1600mm,etc.

Tile:1200x600mm, 600x600mm,600x300mm, 600x400mm, 300x300mm,800x800mm

Countertop: 48x26". 70x26", 78x26", 96"x26", 108"x26"

Island: 72"x36", 96"x36", 96"x40", 108"x44"

Vanity top: 22"x25", 22"x31", 22"x37", 22"x49", 22"x61", 22"x73"

|

Thickness:

|

12mm, 15mm, 18mm, 20mm, 30mm,etc.

|

Surface Finish

|

Polished, Honed,etc.

|

Compress Strength

|

260 MPa

|

Impact Resistance

|

7.72 J

|

Flatness

|

<0.1mm

|

Quality Control

|

All Products Are Checked by Experienced QC Then PA

|

Payment

|

T/T,L/C

|

Samples

|

Free samples for testing absolutely.

|

Package

|

Packed with strong wooden crates and foam, film inside.

|

You may want to involve the aesthetics of the rest of your home in this decision. If you’re looking to mimic the traditional look of granite this is also possible using quartz. Quartz countertops uses 92% naturally sourced quartz, together with high-quality polymer resins, additives and exotic-colored pigments, and processed using cutting-edge procedures and techniques- this allows for the production of a wide range of colors, promotes long-lasting shine, and creates an extremely durable and impenetrable, porous-free surface.

Quartz does not to need to be sealed or treated the way natural stone does. This non-porosity resists bacteria and other pathogens. An antimicrobial surface helps to inhibit the growth of mold and mildew. It can also help prevent the spread of harmful bacteria.This is because quartz countertops are non-porous so they don’t absorb moisture and liquids the way that marble does. You can also eliminate the fear of stunning because a sudden impact on the stone will not cause any marks to appear unlike marble, which is way more susceptible to this. If you were to drop a heavy skillet on marble, for example, a white mark would appear and stun marks are permanent once they occur.

Application:

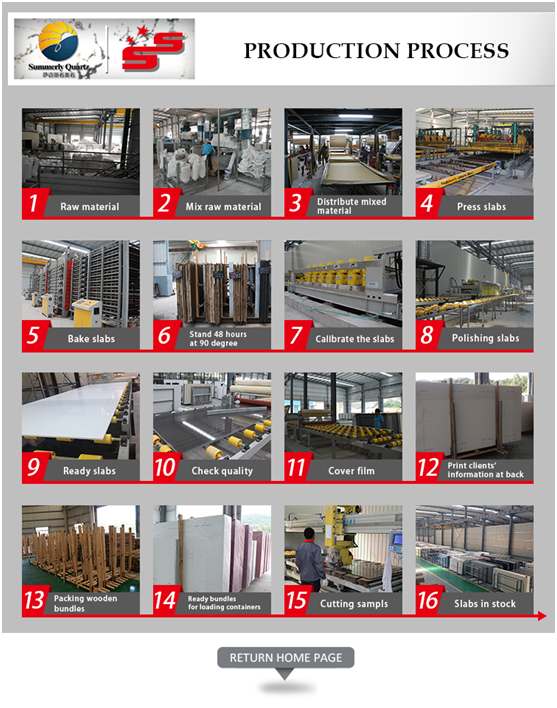

The Production Process:

1. The process begins with a strict inspection of raw materials.

2. The natural quartz raw material and polymer resins and inorganic pigments are put into the mixers and mix together.

3. After mixing, pour them into a mold and form them into slab size.

4. Pressing: Then the slab is compacted by a special vacuum and vibration process at pressure machine.

5. Then the slab is moved to the curing kiln and heated for a period time to make their final strenth and srurdiness.

6. Cut edges, flat , thicknessing and polishing surface to perfect finished.

7. Finally, through quality inspection and plastic film packaging.