|

Product Name

|

SS-L3015

Secret Garden

|

|

Size

|

3000x1400mm,3000x1600mm,

3200x1400mm, 3200x1600mm etc.

|

|

Thickness

|

12 mm,

15 mm, 18 mm, 20 mm, 30 mm

|

|

Surface Finish

|

Polished,

Honed, etc.

|

|

Density

|

2.4 g/cm3

|

|

Specular Gloss

|

>50°

|

|

Ideal Use

|

Kitchen

counter tops, bathroom vanity top, table tops,bench top, island tops,bar

tops, etc.

|

|

Package

|

Packing with

Solid Wooden Crates and Foam Inside.

|

|

Samples:

|

Free samples

are available

|

|

Quality

Control:

|

The quality of

all products is under our control strictly, so we could make sure that what

we offer to you is a superior and quality product.

|

Homeowner and designers love quartz slab

because it has such a stylish and sleek look. Because they are made with 3% resins and 93% raw natural stone, quartz

countertops are less likely to chip when being cropped to fit a space. We

produce quartz in a great variety of colors to suit many tastes and decors. We

are also able to produce pieces that resemble a variety of natural stones so

well that it is difficult to distinguish them from the natural stone.

Quartz stone countertops doesn’t need to be

sealed. It is is a hard, non-porous surface, making it easy to clean and

maintain. All you need is just soap and water or a mild detergent. Quartz’s

waterproof nature also means you do not have to worry about bacteria

infiltrating your quartz. Quartz is so easy to care for that it makes cleaning

your countertops a breeze. It’s an incredibly durable, non-porous surface that

resists stains, scratches and the other potential problems you might see with

natural stone countertops.

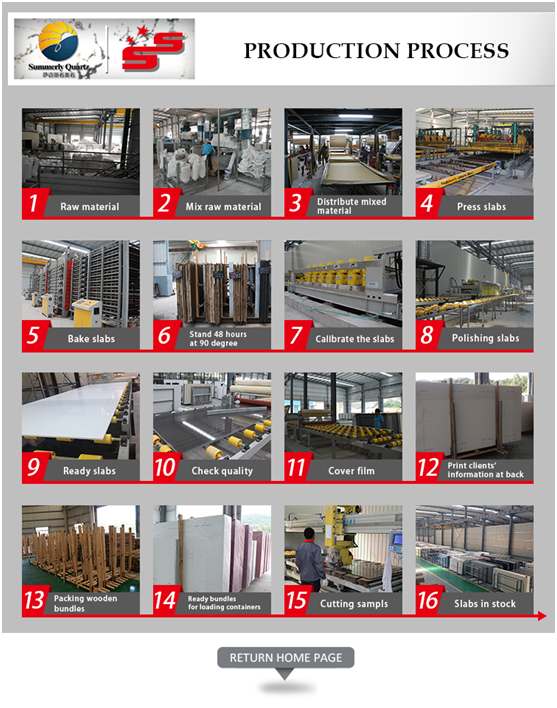

Production Engineering:

1. The process begin with a rigorous

inspection of raw materials.

2. Feeding natural quartz raw material and

polymer resins and inorganic pigments in to mixers and blending them together.

3. After stirring the mixture, then pouring

them into a mold and form them into slab size.

4. Pressing: Then the slab is compacted by a

special vacuum and vibration process at pressure machine.

5. The slab then moved to the curing kiln and

heated for a period time which give them ultimate strength and solidity.

6. Trimming edges, leveling , thicknessing

and polishing surface to perfect finished.

7.Finally, the quartz stone slabs passed

through quality inspection and packed with a plastic film.

Packing wooden

crate (slab) wooden box (tiles/

countertop)