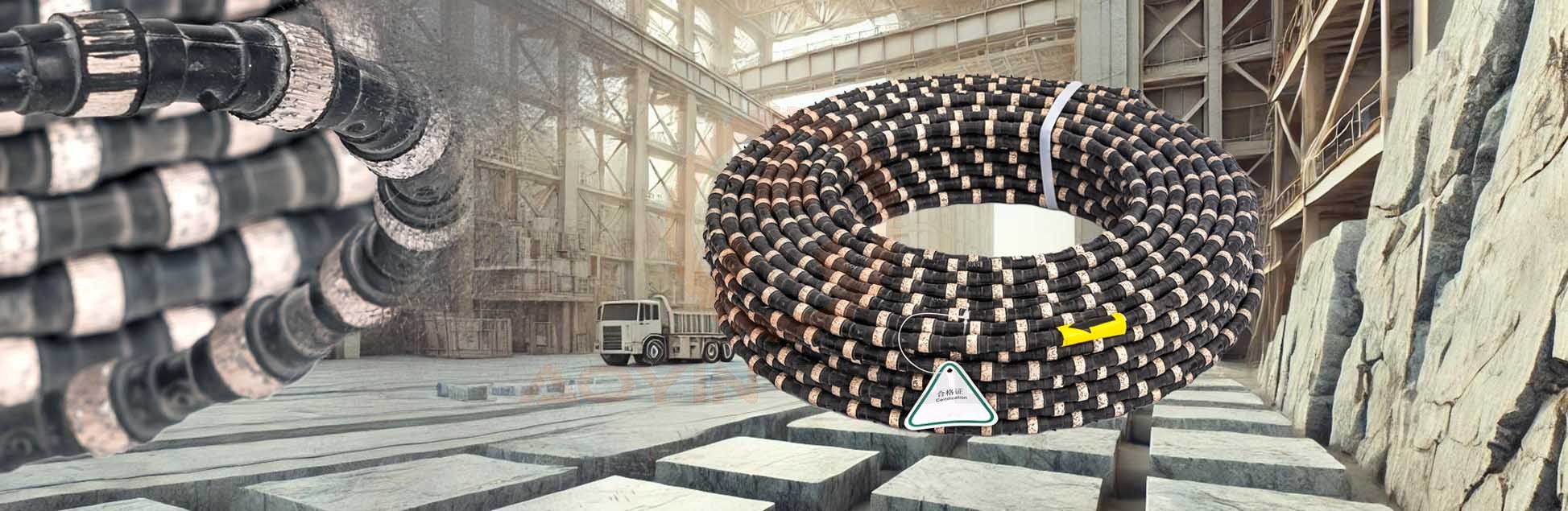

Rubber Diamond Wires for Granite and Sandstone Mining

Our Rubber Diamond Wires are designed for efficient and precise cutting in granite and sandstone mining. With a durable rubber coating and high-performance diamond beads, these wires ensure smooth, vibration-free cutting, enhancing productivity in both wet and dry conditions.

Rubber Diamond Wires for Granite and Sandstone Mining

Product Features:

These Rubber Diamond Wires are the perfect solution for professional granite and sandstone extraction, offering high cutting precision, shock absorption, and extended service life. With customizable wire lengths and bead configurations, these wires ensure optimized performance in the toughest conditions, minimizing tool wear and operational downtime.

Key Selling Points

- Durable and Flexible Design:

Featuring a rubber coating that protects the diamond beads, the wire offers enhanced durability and flexibility, ensuring longer service life in harsh environments. -

High-Precision Cutting:

The high-grade diamond beads ensure clean and accurate cuts, reducing material waste and enhancing productivity. -

Reduced Vibration:

The flexible rubber structure absorbs cutting forces, providing smoother operation and less wear on equipment. -

Versatile Applications:

Suitable for both wet and dry cutting, these wires can handle a variety of mining conditions and materials, including granite, sandstone, and composite materials. -

Customizable Solutions:

Available in various wire lengths and bead configurations to suit different project requirements.

Key Product Parameters:

| Technical Specification | Details |

| Wire Diameter | 8.0mm, 9.0mm, 10.5mm,11.5mm (customizable) |

| Beads Per Meter | 28-32 beads per meter (standard options) |

| Bead Diameter | 10mm, 11mm, 12mm (customizable) |

| Cutting Speed | 15-35 m²/h (depending on material hardness) |

| Cutting Type | Wet and Dry Cutting |

| Tensile Strength | 2500N-3000N (ensuring stability during prolonged cutting) |

| Service Life | 20-25 m² per meter (depending on material and conditions) |

| Cutting Applications | Granite, Sandstone, Limestone, Composite Materials |

| Cable Structure | Rubber Coated, absorbs vibrations, enhances tensile strength |

| Cutting Length | Standard: 10m, 20m, 50m (custom lengths available) |

Applications:

- Granite Mining

- Sandstone Extraction

- Quarry Operations

- Architectural Stone Cutting

- Large-Scale Construction Projects

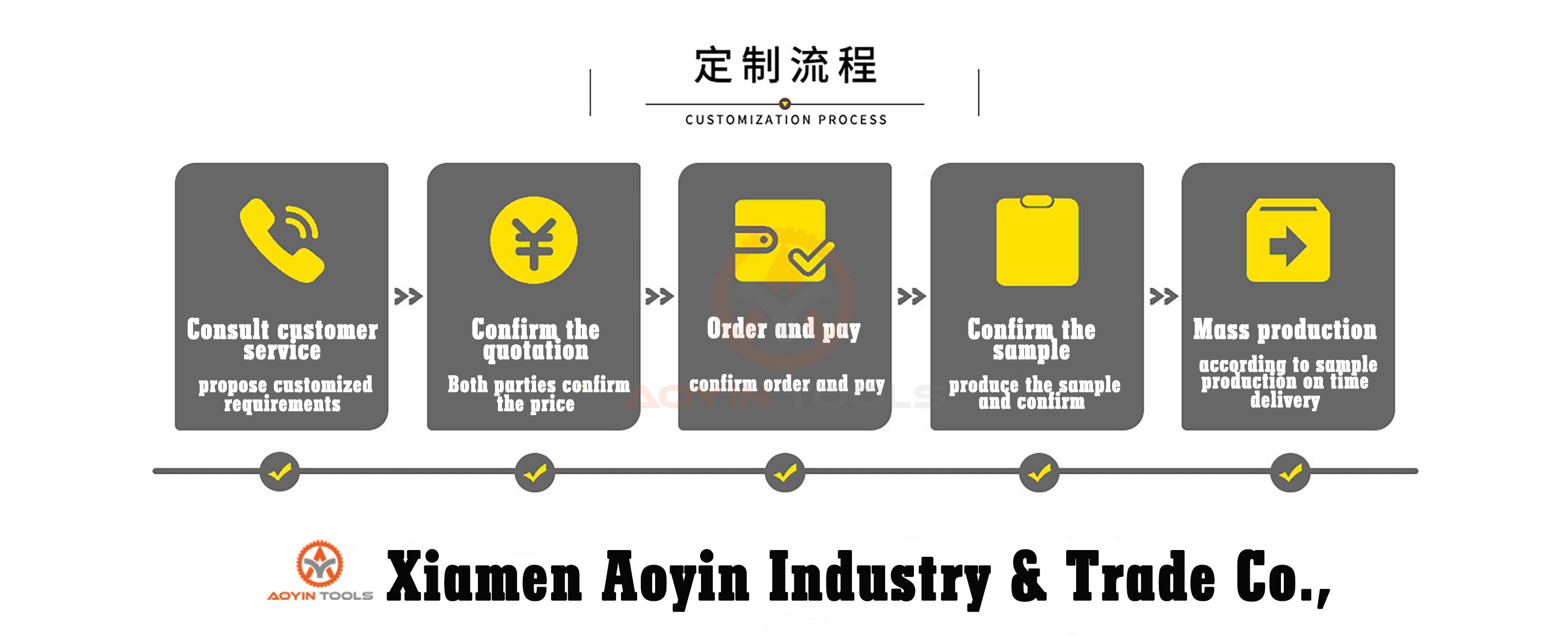

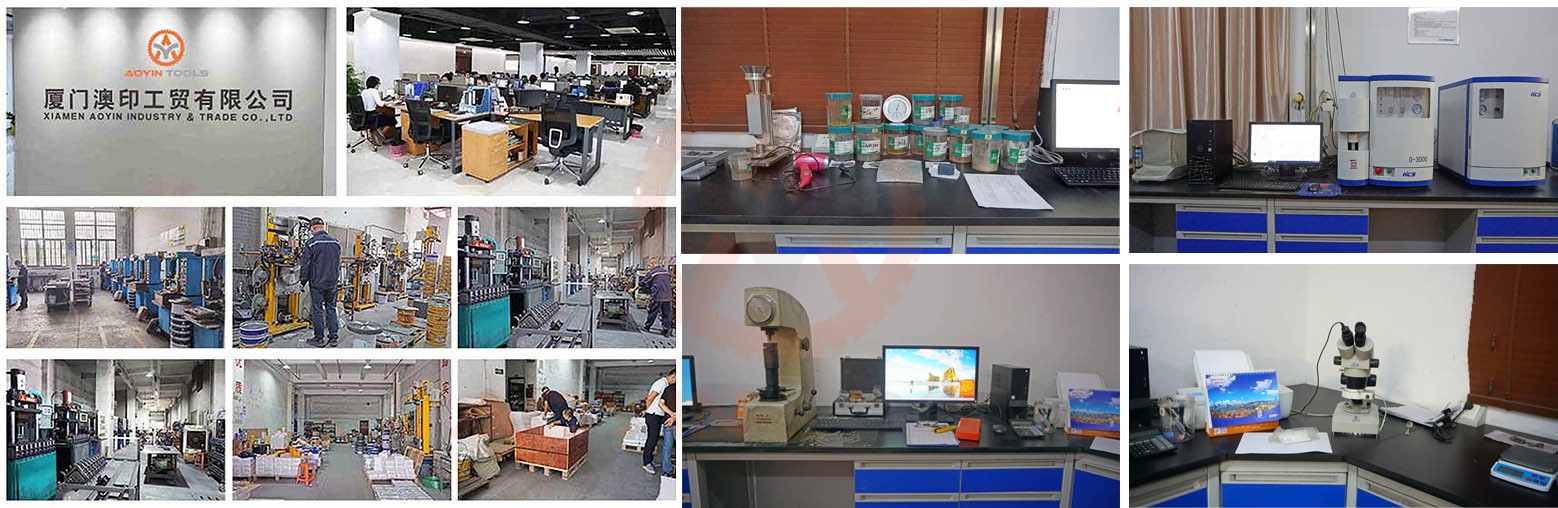

Company Advantages:

-

Extensive Experience

Over 10 years in the diamond tool industry. -

Custom Solutions

Tailored product specifications to meet diverse cutting needs. -

Strict Quality Control

Rigorous testing ensures durability and cutting precision. -

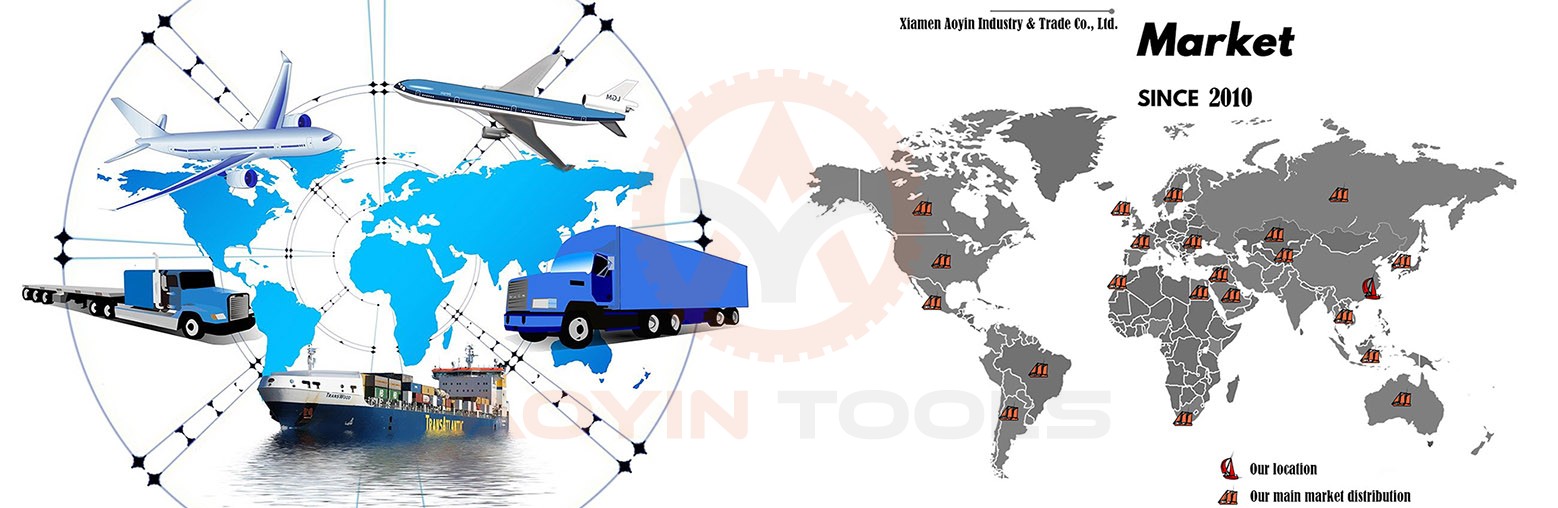

Global Reach

Efficient logistics and worldwide delivery. -

Technical Support

Professional support and reliable after-sales service.

Our dedicated customer service team is committed to providing prompt assistance and ensuring your complete satisfaction throughout the buying process.

FAQ

-

What materials can these diamond wires cut?

Our Rubber Diamond Wires are designed for cutting granite, sandstone, and other natural stones. They are suitable for various stone extraction and mining operations. -

Are these wires suitable for both wet and dry cutting?

Yes, the wires are designed for both wet and dry cutting, providing flexibility for different project needs. -

What is the lifespan of the wire?

The lifespan of the diamond wires depends on the material being cut and operational conditions, typically ranging from 20-25 m² per meter of wire. -

Can the wire length be customized?

Yes, we offer customizable wire lengths to suit specific project requirements. Please contact us for more details. -

What is the cutting speed of these diamond wires?

The cutting speed ranges from 15-35 m²/h, depending on the hardness of the stone and operational factors.