BCL-4020 Single worktable fiber laser cutting machine

The gantry type double structure,stable operation;

Welding-bed steel after aging stress,large five face marching center one -time cutting molding;

Beams with high-strength aviation aluminum after aging treatment after cnc precision cutting,low inertia,high flexibility and validity to cut fasterand more power efficient;

Put a lot of die-casting mold parts more precise and consistent;

Extended type can be saved automatically exchange platform,so as to enable the cutting range is bigger and save more time and moeny;

According to the needs of different process-users can choose a variety of different brands lf laser power.

|

Product Parameters

|

|

Brand and manufacture

|

BCSK LASER

|

Machine Model

|

BCL-4020

|

|

working area

|

2000*4000mm

|

Laser power

|

Selectable

|

|

Machine weight

|

5800KG packing

|

Fiber laser Generator

|

Max,IPG Brand,nLIGHT,ect

|

|

Laser wavelength

|

1070mm-1080mm

|

Laser Beam quality

|

<0.373mrad

|

|

Worktable

|

Sawtooth with pneumatic easy

moving attachment

|

Fiber Laser cutting head

|

Switzerland Raytools auto focusing

|

|

Focus lens

|

Raytools

|

Working life of fiber module

|

More than 100000 hours

|

|

Motors & Drivers

|

YASKAWA servo motor made in

Japan or other imported

|

Reducer

|

Japan Shimpo

|

|

Guide Rails

|

High accuracy linear brand from

Taiwan

|

Transmit system

|

DUAL drive rack and pinion 4 Focus lens

|

|

Chain system

|

Enclosed high quality

|

Water Chiller

|

Hanli or Tongfei

|

|

Control system

|

Professional laser control

system--Cypcut

|

Position type

|

Red Dot pointer

|

|

Cutting thickness

|

≤5mm(stainless steel)

|

Max. Idle Running Speed

|

100M/min

|

|

≤12mm(carbon steel)

|

|

Geometric Position Accuracy

|

within ±0.08mm/M

|

Max Cutting Speed

|

32M/Min

|

|

Reorientation accuracy

|

within ±0.05mm/M

|

Lubrication system

|

Auto Electrical motored,wholly and sound

|

|

Min. Line Width

|

±0.02mm

|

Power Consumption

|

10-13KW total

|

|

Power supply Voltage

|

380V/50Hz/60Hz

|

Auxiliary gas system

|

Japan SMC series components, dual air inlets,

low pressure piercing , automatic pressure

adjustment and switching

|

|

Auxiliary Gas for cutting

|

Oxygen, Nitrogen, Air

|

Compatible software

|

Autocad, Coreldraw, etc

|

|

Graphic format

|

DXF/PLT/AI/

|

Working method

|

Industrial PC control with console desk and

romote

|

|

Total power protection rating

|

IP54

|

|

|

Guideway surface

Welding the whole steel plate, milling the guide surface through the large gantry to ensure the stability of the use for more than 20 years.

1- Taiwan“K.H”rack,din6 precision(or YYC ect.)

2-Positioning pin design to prevent rack displacement

1-Taiwan “HIWIN” guide rail,High-precision.

2-Design of baroclinic block to prevent displacement of guide rail

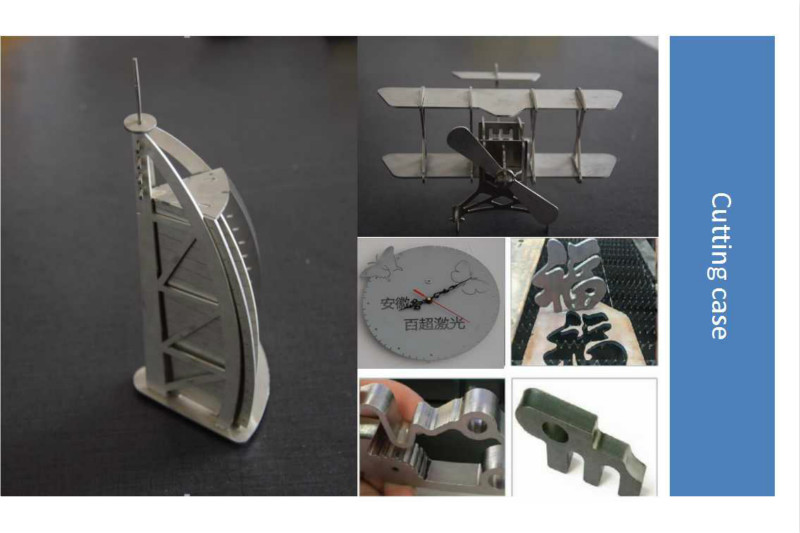

Appicable Industry and Cutting Samples

This machine is widely used in various industries such as advertising decoration,kitchen ware,engineering machinery,steel and iron,automobile,metal plate chassis,air-conditioner manufacturing,metal plate cutting,etc