Production Description

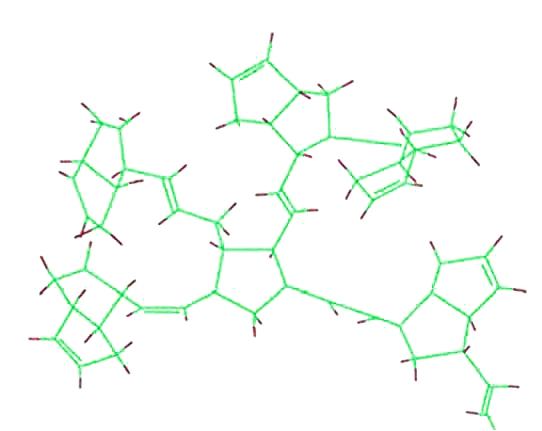

Polydicyclopentadiene (PDCPD) is a new type of thermoset material in the field of polymer materials, PDCPD material has both high impact strength and high flexural modulus, and there was no this kind of characteristics of engineering plastics before, now more and more materials engineers are beginning to recognize, pay attention to, and use this new material.

A WIDE RANGE OF PDCPD APPLICATION

PDCPD is most suitable for the manufacture of construction machinery, agricultural machinery, trucks, automobile coverings, integrated large-scale molding products represented by sanitary equipment, and purification tanks. It is the ideal material to replace glass fiber reinforced plastic, some plastics, metal sheet metal parts, carbon fiber, and alloy in the future, and it is also the high-quality choice for lightweight equipment in many new industries such as new energy automobile, wind power generation, unmanned aerial vehicle, tunnel template, robot and so on, and the application field is extremely broad, and it can be widely used in the fields of automobile manufacturing, construction engineering template, agricultural machinery, military, civil, medical, scientific research and national defense, and it has great market potential and development space. development space is huge.

| Offshore mining tools |

Chemical storage containers |

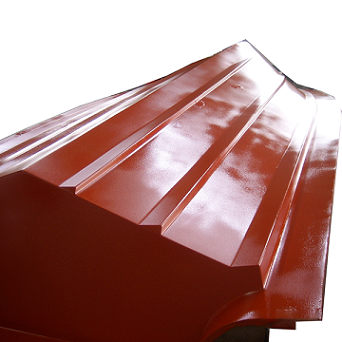

Truck Air Conditioner Outer Unit Cover |

Yacht hulls |

|

|

|

|

PDCPD Products High Properties Test Reference

|

Content

|

Unit

|

Testing Method

|

Content

|

Unit

|

Testing Method

|

|

Tensile strength

|

47.5MPa

|

GB/T 1040.2-2006

|

Rockwell hardness

|

115

|

GB/T3398.2-2008

|

|

Tensile modulus

|

1900MPa

|

GB/T 1040.2-2006

|

Distortion temperature

|

110.5

|

GB/T1634.2-2004

|

|

Elongation at break

|

12.30%

|

GB/T 1040.2-2006

|

Density

|

1.03g/cm³

|

GB/T1033.1-2008

|

|

Compressive strength

|

60.8MPa

|

GB/T 1041-2008

|

Glass transition temperature

|

169℃

|

GB/T19466.2-2004

|

|

Bending strength

|

75.6MPa

|

GB/T9341-2008

|

Burning horizontally

|

HB40

|

GB/T2408-2008

|

|

Bending modulus of elasticity

|

2053MPa

|

GB/T9341-2008

|

Water Absorption

|

0.10%

|

GB/T1034-2008

|

|

Notched impact strength

of cantilever beam (23℃)

|

33.1

|

GB/T1843-2008

|

Automotive interior combustion

Performance (burning rate)

|

A-0

|

GB 8410-2006

|

|

Notched impact strength of

cantilever beam (-40℃)

|

12.8

|

GB/T1843-2008

|

Rockwell hardness

|

115

|

GB/T3398.2-2008

|

Ten Advantages of PDCPD Products Properties

1. Wide molding range: two-component, low-viscosity liquid resin injection molding, shape, runner, and pressure restrictions are small, can produce large, complex shapes, the wall thickness of the workpiece.

2. Equipment Investment: simple molding process, low pressure and temperature requirements, less investment in molding equipment, low mold costs, long service life of the mold, small amortization costs

3. Good balance of physical properties: excellent and balanced physical properties, especially the combination of high impact resistance and high rigidity, can get lightweight, high strength, rugged, and durable parts.

4. Temperature and corrosion resistance: outstanding resistance to temperature change, high temperature does not creep, low temperature does not cause brittle crack, can be used in -40 ~ 100 ℃ environment for a long time: excellent corrosion resistance, especially acid resistance, alkali resistance is outstanding.

5. High product precision: the product deformation is small, the size error is small, and the consistency of the workpiece is high; in general, the control of the size error of the workpiece can reach the GB/T1804-m level.

6. Excellent decorative properties: the surface of the molded parts is easy to form a dense oxide film with good adhesion to paint. It can also be plated, water transfer printing, and other surface decorative treatments.

7. Good designability: high degree of design freedom, can be pre-embedded, riveted, glued, self-tapping, and drilling, can be unequal thickness structure, sandwich structure, composite structure, etc.

8. High molding efficiency: short mold development cycle. Less production labor, high molding efficiency, product molding cycle is generally 3 ~ 5 min. can be configured with robot to achieve automated demolding, trimming, and so on.

9. Good Safety and environmental protection: no fiber and dust, no poison and pollution, less edge residue, recyclable and harmless reuse, reuse more ways, high added value.

10. Wide range of applications, design freedom, applied in various automobiles, engineering equipment, medical equipment, chemical equipment, entertainment facilities, military, civilian, and other fields. Excellent performance, PDCPD material process, green, lightweight, high strength, green, fast and economical industrial closure.