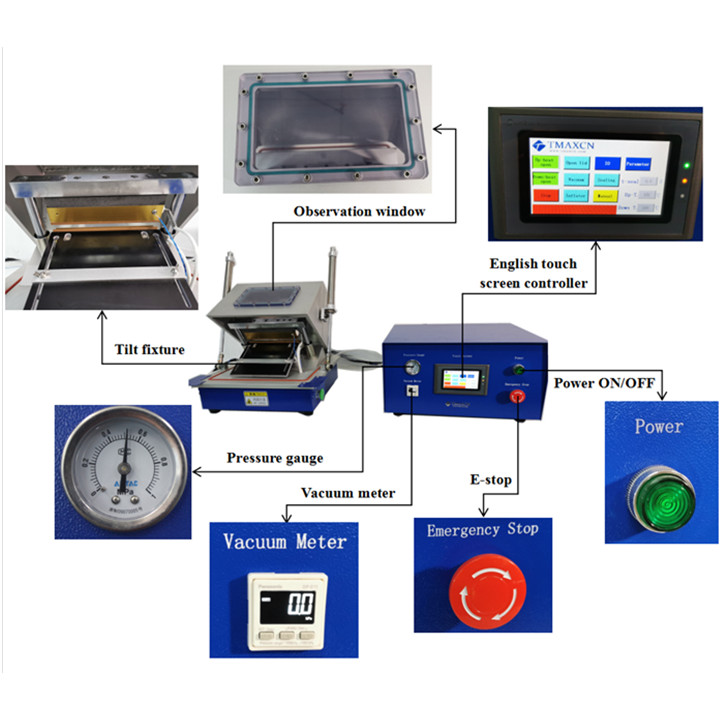

Vacuum Sealer For Pouch Cell Pre-Sealing After Electrolyte Injection

This equipment is mainly suitable for vacuum hot sealing of pouch cell after electrolyte filling and standing; the machine can automatically complete vacuum thermal sealing of aluminum laminated film by precisely controlling the main vacuum pumping box and pneumatic heat sealing components.

* the head is made of copper material, which has good heat transfer effect, saves power consumption, improves work efficiency and saves energy compared with similar products;

*The pressure of upper and lower heads can be adjusted by pressure regulating valve to meet the requirements of different process parameters;

*The upper and lower heads are driven by cylinder and guided by two linear guide sleeves, which can move up and down flexibly and guide accurately

Ensure the requirement of parallelism after edge sealing;

*Through the perspective window, we can observe the changes in the cavity when working.

*The cover cavity is driven by cylinder and guided by rotating guide sleeve, which can move up and down flexibly and guide accurately to ensure the sealing requirements of products.

*It can be used for batteries of different specifications, and the adjustment is simple and convenient.

*The main engine and control box are designed separately, so that the machine can work in glove box or on assembly line.

*Simple operation, beautiful appearance, small volume and light weight.

|

Chamber

|

The chamber is made of aluminum alloy, which is corrosion resistant and has a firm structure;

|

|

Vacuum degree

|

The vacuum degree can be adjusted up to -95Kpa (the buyer shall provide the vacuum pump);

|

|

Head temperature

|

Room temperature~250℃, temperature adjustable;

|

|

Temperature control accuracy

|

±2℃;

|

|

Heat sealing pressure

|

0~7Kg/cm2 adjustable;

|

|

Heat sealing time

|

0~99 seconds adjustable;

|

|

Edge sealing width

|

5±0.4mm (can be customized)

|

|

Maximum edge sealing length

|

200mm

(can be customized, such as 300/400/500mm sealing length)

|

|

Seal thickness range

|

60~300um

|

|

Seal thickness accuracy (mm)

|

Sealing thickness difference between any two points<15um

|

|

Air consumption

|

About 0.2L compressed gas per seal once.

|

|

Working speed of air compressor

|

≥180 times/h

|

|

power

|

Using 300w heating tube, the power consumption when heating is about 0.6KW.

|

|

Power Supply

|

220V/50Hz;

|

|

Compressed air source

|

0.5~0.8Mpa; When used in the glove box, the cylinder power source must use the same working gas used in the glove box;

|

|

Working chamber

|

470mm*485mm*435mm;

|

|

Control box

|

420mm*325mm*225mm

|

|

Equipment weight

|

About 50Kg

|