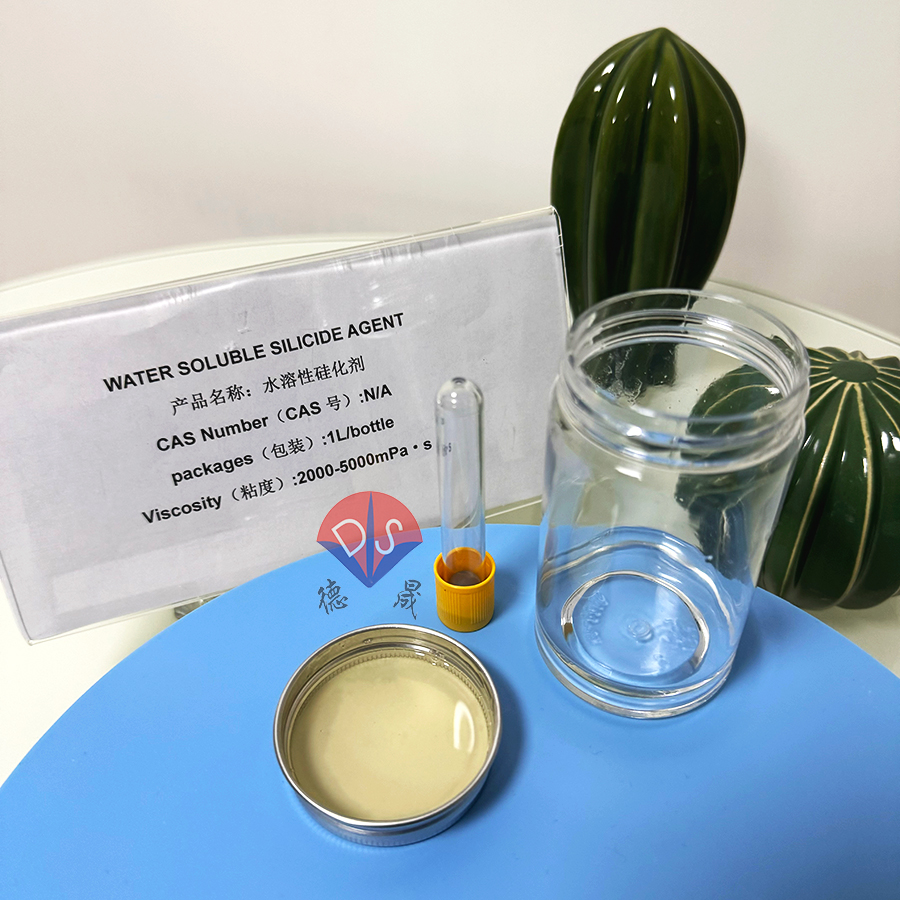

[Product performance] colorless to light yellow transparent liquid, soluble in ethanol, petroleum ether and other organic solvents, rain water hydrolysis.

[Physical indicators]

- Appearance: colorless to light yellow transparent liquid;

- Content: (at 25 ℃) ≥ 90.0%

- Density: (at 25 ℃) 0.88g/cm3~ 0.89g /cm3

- Boiling point: 125 ℃ / 0.24kpa

[Usage]

- Take 1 part of silicide and add 100-200 parts of petroleum ether (60-90 ℃ boiling range) (concentration is 0.5-1.0%), and mix well.

- Spray the mixed solution into the test tube, make the inner wall of the test tube uniformly adhere to a layer of the above solution, or soak the test tube in the above solution, and then take itout after a short stay.

- Put the glass tube mouth downward, drain the solution, place it at room temperature for 2-4 hours to cure, and then add other reagents after the tube wall is dry and the petroleum ether volatilizes completely, or dry it at high temperature of 90 ℃.

- Place the plastic test tube at room temperature for 2-4 hours to cure, and add other reagents after the cure is complete, especially when the reagent is an aqueous solution, it can only be added after it is fully cured and the petroleum ether is completely volatilized.

[Special storage conditions and methods] the product is sealed and protected from light and water under normal temperature and pressure. It is suggested to store it at 0-15 ℃, and the prepared silicon liquid should be sealed and waterproof.

[Precautions]

- The high-efficiency silicideagentis a high polymer organosilicon material, which is hydrolyzed and gelatinous in case of water. During tube silicification and solution preparation, the tube, container and measuring tool must be kept dry and clean.

- This product is mainly used for silicification of glass or plastic surface. In view of the differences of products, technology and environment of each enterprise, small batch test should be carried out before batch use of this product.