Model No |

SS1831--Holly-White |

Type |

Artificial Quartz Stone Countertop |

Size |

3000x1400mm, 3000x1600mm, 3200x1600mm,etc |

Thickness |

12mm, 15mm, 18mm, 20mm, 30mm |

Stone Density |

2.7g/cm3 |

Rupture strength |

55Mpa |

Water absorption |

0.02% |

QC Control |

Polished degree:90 degree or up.As customs' requirement Thickness tolerance: /-0.5mm All products checked by experienced QC and then pack |

Package |

Foam inside strong seaworthy wooden crates with reinforced straps outside |

Application |

Bar-tops and table-tops,Wall surfaces and other décor-trim, kitchen countertop and bathroom vanity top,etc. |

Your kitchen or bathroom just got the ultimate upgrade: brand-new quartz countertops. Quartz is beloved for being gorgeous to look at and low maintenance.While not entirely new, Quartz is a material that has recently exploded onto the home renovation scene. Considered to be of the hardest materials in the world, Quartz has many unique properties that make it an ideal resource for kitchen countertops and other surfaces in new and renovated homes. Quartz comes in a wide variety of colors and patterns, is easy to maintain because it’s already perma-sealed during production, and is extraordinarily durable. It has the charm and class of natural stone, even though it is engineered.

Quartz is very resistant to scratching, but it is always better to be on the safe side and prevent anything unwanted from happening. When cutting, use a board, especially when working with porcelain knives. This will also prevent the dulling of the knives. Quartz countertops are one of the easiest countertop products to maintain. Unlike its counterparts, quartz does not need any sealers. In fact, you do not need to seal your countertops each year since they are non-porous. Instead, you will merely need clear dish soap and a damp, soft rag to clean it. You can easily remove most surface stains with a cleaning agent. However, remember to not use scouring pads and harsh cleaning products because they can damage the bond between quartz and resin.

SS1831--Holly-White(Leathered):

SS1831--Holly-White(Polished):

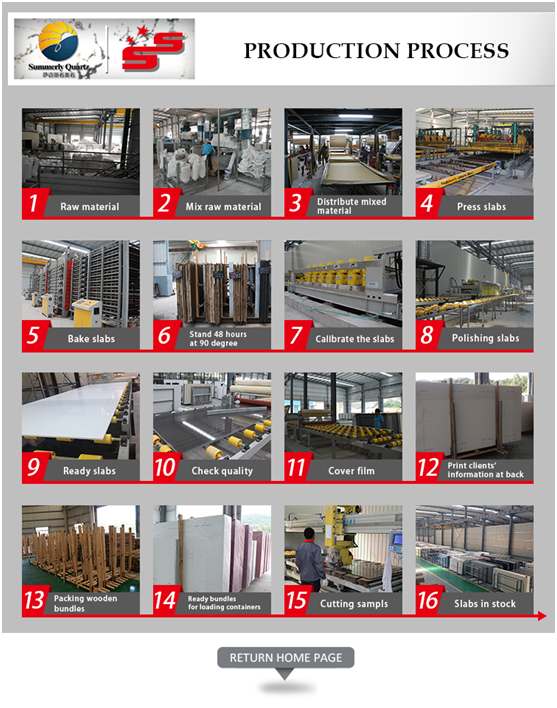

The Production Process:

1. The process begins with a strict inspection of raw materials.

2. The natural quartz raw material and polymer resins and inorganic pigments are put into the mixers and mix together.

3. After mixing, pour them into a mold and form them into slab size.

4. Pressing: Then the slab is compacted by a special vacuum and vibration process at pressure machine.

5. Then the slab is moved to the curing kiln and heated for a period time to make their final strenth and srurdiness.

6. Cut edges, flat , thicknessing and polishing surface to perfect finished.

7. Finally, through quality inspection and plastic film packaging.