|

Model No

|

SS6142 Nice White

|

|

Color

|

white

|

|

Slab Size Available

|

3000x1400mm, 3000x1600mm,3200x1600mm,etc.

|

|

Thickness

|

15mm, 18mm, 20mm, 30mm.

|

|

Samples

|

Free Small Quartz Sample

|

|

OEM Service

|

Yes

|

|

Harness

|

7 Mohs

|

|

Payment Term

|

T/T (30% deposit), Irrevocable L/C at sight

|

|

Advantage

|

1. High gloss for a long time

2. No scratch

3. No color change

4. High temperature resistance

5. Corrosion resistant

|

|

Tech Support

|

1.QC staff control each productive process and ensure excellent quality

of final finished products;

2.CAD support;

|

Quartz countertops are sleek, chic,

versatile and contemporary—we can hardly think of better qualities to bring to

your kitchen or bathroom design. Quartz, also called engineered stone, is one

of the hardest minerals on earth. Thus when used as a countertop option in

homes, it is arguably the most durable choice. Unlike other mined natural stone

slabs, quartz is produced in a factory. Here are some other reasons people love

quartz countertops:

• Higher density &

Higher hardness at Mohs’ hardness 6~7 degree.

• Easy to maintain and

clean (mild soap and water)

• Natually anti-bacterial

because it’s non-poress

• Resists stains and is

impervious to heat and acid

• High surface harness

keeps quarts stone resistant to scratch & impact.

Usage:

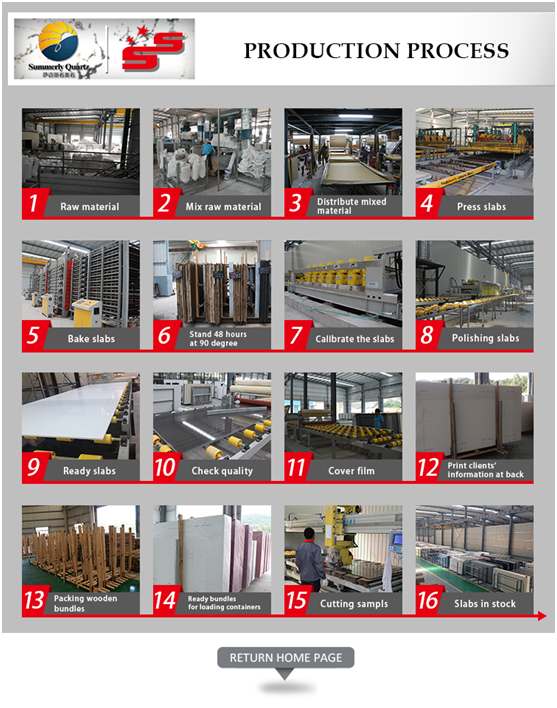

The Production Process:

1.

The process begins with a strict inspection of raw materials.

2.

The natural quartz raw material and polymer resins and inorganic pigments are

put into the mixers and mix together.

3.

After mixing, pour them into a mold and form them into slab size.

4.

Pressing: Then the slab is compacted by a special vacuum and vibration process

at pressure machine.

5. Then

the slab is moved to the curing kiln and heated for a period time to make their

final strenth and srurdiness.

6.

Cut edges, flat , thicknessing and polishing surface to perfect finished.

7.

Finally, through quality inspection and plastic film packaging